Top Advantages of Employing Professionals for Welding Inspection Madison

Top Advantages of Employing Professionals for Welding Inspection Madison

Blog Article

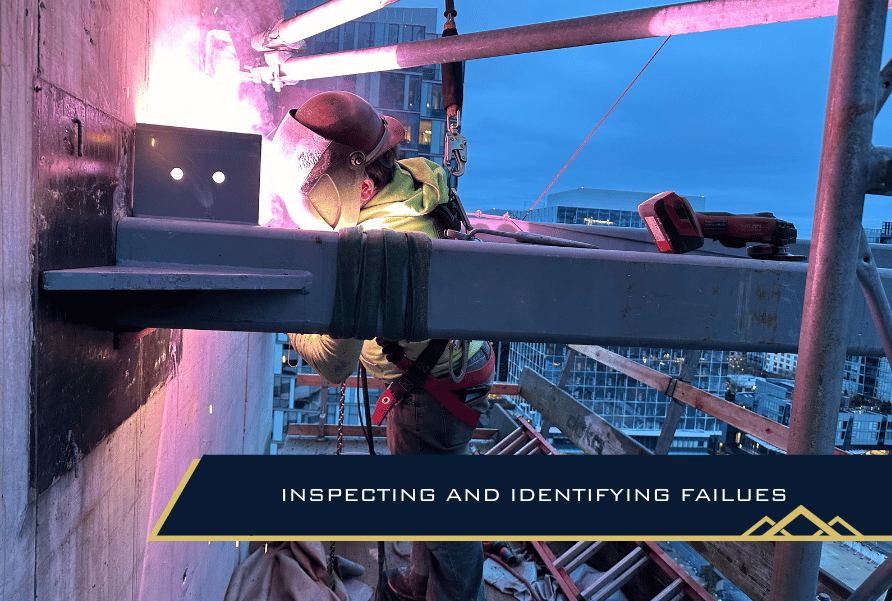

Understanding the Fundamentals of Welding Examination to Ensure Quality and Security

In the realm of modern-day engineering, welding assessment stands as a keystone for making certain both the quality and security of architectural creations. What are the subtleties of these inspection approaches that make them indispensable for maintaining structural integrity?

Importance of Welding Inspection

In the realm of industrial fabrication, the relevance of welding evaluation can not be overemphasized. Welding inspection plays a vital function in making sure the honesty, safety and security, and long life of welded frameworks (Welding Inspection Madison).

The procedure of welding inherently involves complicated variables, including temperature level, material residential properties, and ecological problems, all of which can influence the top quality of the weld. An extensive examination identifies issues such as cracks, porosity, and incomplete blend, which can jeopardize the stamina and integrity of the weld. By spotting these concerns early, restorative activities can be taken, consequently reducing the threat of failure and associated expenses.

Additionally, welding examination adds to regulatory conformity, as numerous markets are controlled by rigorous security standards and guidelines. Failure to abide by these laws can result in legal liabilities and punitive damages. Inevitably, welding inspection not only safeguards physical frameworks but likewise shields human lives and maintains market online reputations.

Trick Welding Assessment Approaches

Although welding assessment is crucial to guaranteeing the quality and safety of bonded frameworks, it is the details approaches utilized that determine the efficiency of the examination process. Trick welding evaluation approaches can be extensively classified right into non-destructive screening (NDT) and devastating testing. Non-destructive testing approaches such as visual examination, ultrasonic screening, radiographic testing, magnetic fragment testing, and liquid penetrant testing are primarily utilized to examine the homes of a weld without causing damages. Visual inspection is typically the very first step, including a detailed exam of the weld's surface area for flaws like fractures or porosity.

Radiographic and ultrasonic testing are advanced methods that allow inspectors to assess the interior integrity of the weld. Ultrasonic testing makes use of high-frequency acoustic waves to spot stoppages, while radiographic testing employs X-rays or gamma rays to generate an image of the weld's interior. Magnetic particle screening and liquid penetrant screening are surface inspection techniques made use of to situate surface area and near-surface defects. On the other hand, damaging screening approaches include physically cutting the weld or damaging to evaluate its mechanical properties. These thorough evaluation techniques guarantee that welds satisfy market criteria and security requirements, consequently ensuring architectural integrity and performance.

Duty of Licensed Assessors

Certified assessors play a crucial function in the welding inspection procedure, making sure that all welds abide by stringent industry standards and security policies. Their proficiency is crucial in identifying issues or abnormalities that may endanger the structural honesty of a weld. By diligently taking a look at each weld, certified examiners assist avoid potential failures that could cause pricey repair work or hazardous crashes.

To come to be licensed, examiners have to go through extensive training and testing, which familiarizes them with various welding techniques, materials, and testing approaches. This comprehensive knowledge allows them to evaluate weld high quality successfully and make informed judgments concerning their safety and security and integrity. Furthermore, licensed assessors excel in analyzing plans and specs, ensuring that the welding job straightens with the job's style requirements.

An essential component of their role is to document their searchings for completely, offering a detailed document of the assessment process. This documentation is crucial for traceability and navigate to these guys accountability, working as a main document of conformity with market requirements. Certified assessors likewise play a crucial function in assisting in communication between job stakeholders, supplying understandings and suggestions to boost welding methods and results. Their contribution is vital in preserving high levels of quality and safety and security in welding operations.

Devices Made Use Of in Welding Inspection

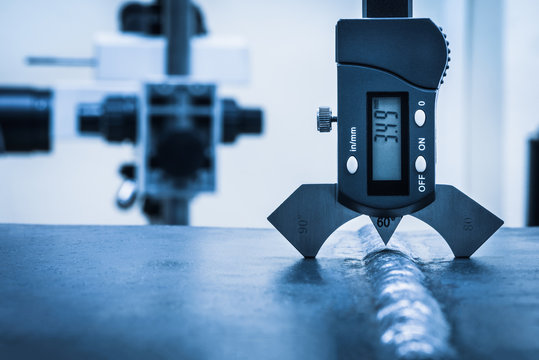

Welding assessors rely upon a variety of specialized devices to do their duties effectively, ensuring each weld meets the necessary requirements. Among these tools, aesthetic assessment help like multiplying glasses and mirrors are essential, permitting assessors to very closely analyze welds for surface flaws such as splits, porosity, and undercut. Calipers and fillet weld assesses are necessary for measuring weld measurements to validate conformity with layout specs.

Advanced devices extend beyond visual help, including non-destructive screening (NDT) devices. Ultrasonic screening devices are essential in spotting subsurface problems, utilizing sound waves to disclose inner interruptions without compromising the weld's honesty. Radiographic testing employs X-rays or gamma rays to catch pictures of a weld's inside, highlighting potential issues.

Magnetic fragment testing is an additional crucial tool, especially for finding surface area and near-surface stoppages in ferromagnetic products. By applying magnetic other areas and ferrous fragments, assessors can determine flaws that may otherwise be unseen.

Dye penetrant evaluation is commonly used for non-ferrous materials, providing a contrast-enhanced click here for more visual look for surface-breaking defects. Welding Inspection Madison. With each other, these tools make it possible for welding assessors to comprehensively evaluate weld top quality, making certain safety and security and reliability in various applications across markets

Guaranteeing Structural Honesty

Welding procedures need to follow recognized requirements and codes, such as those defined by the American Welding Culture (AWS) or the International Organization for Standardization (ISO) These standards ensure that the welds can hold up against environmental elements and functional anxieties. Certified and accredited welders play a crucial role in this procedure, as their experience guarantees that strategies are applied correctly, lessening defects such as fractures, porosity, and incomplete blend.

Post-weld assessment is another important element of validating structural integrity. Non-destructive screening (NDT) approaches, consisting of ultrasonic testing and radiographic testing, are used to find subsurface problems without jeopardizing the bonded framework. These evaluations validate that the welds fulfill the called for top quality requirements, offering assurance of their durability and integrity. Eventually, making certain structural honesty in welding not just safeguards human lives however additionally safeguards investments and enhances the longevity of crafted structures.

Conclusion

The principles of welding assessment are important for keeping the high quality and safety of welded frameworks. The use of specialized devices even more improves the evaluation procedure, ultimately guarding human lives and prolonging the life-span of welded buildings.

Welding assessment plays a crucial duty in guaranteeing the stability, safety, and durability of bonded structures.Although welding assessment is critical to guaranteeing the top quality and safety of welded frameworks, it is the details methods utilized that establish the performance of the inspection procedure. Key welding evaluation techniques can be generally categorized right into non-destructive screening (NDT) and destructive testing.Licensed examiners play a crucial duty in the welding inspection process, making sure that all welds abide with rigorous sector standards and safety policies.The basics of welding assessment are necessary for keeping the top quality and safety and security of bonded frameworks.

Report this page